Ichi chinyorwa chinosuma mazano ekugadzira uye kugadzirisa maitiro epurasitiki lunch box chivharo zvakadzama, uye chimiro chezvikamu zvepurasitiki, zvigadzirwa zvekuongorora kwakadzama, dhizaini inonzwisisika ye mold tekinoroji.

Mazwi akakosha: jekiseni mold;Lunch box.Molding process

Chikamu Chekutanga:Kuongorora kwezvikamu zvepurasitiki uye yekutanga kusarudzwa kwejekiseni muchina

1.1Raw zvinhu uye kuongororwa kwekuita kwepurasitiki lunch box

Iri bhokisi rekudya kwepurasitiki ndiro chigadzirwa chepurasitiki chakajairika muhupenyu hwezuva nezuva, chinonyanya kushandiswa kubata chikafu.Tichifunga nezvekunyanya kushandiswa kwayo, kuongororwa kwakazara kwekushanda kwemapurasitiki akasiyana-siyana, kusarudzwa kwezvinhu zve polypropylene (PP).

Polypropylene (PP plastiki) imhando yehuremu hwepamusoro, isina cheni yepadivi, yakakwira crystallization yemutsara wepolymer, ine yakanakisa yakazara zvivakwa.Kana isina ruvara, chena inopenya, yakisi;Yakareruka kupfuura polyethylene.Kujeka zvakare kuri nani pane polyethylene.Mukuwedzera, kuwanda kwepolypropylene idiki, chaiyo giravhiti ye 0.9 ~ 0.91 magiramu / cubic centimita, goho simba, elasticity, kuoma uye kusimba, kumanikidza simba kwakakwira kupfuura polyethylene.Tembiricha yaro yekuumba ndeye 160 ~ 220 ℃, inogona kushandiswa ingangoita 100 madhigirii, uye ine yakanaka magetsi emagetsi uye yakakwirira frequency insulation haina kukanganiswa nehunyoro.Mvura yaro yekutora mvura yakaderera kupfuura polyethylene, asi nyore kunyunguduka kuputika kwemuviri, kushamwaridzana kwenguva refu nesimbi inopisa zviri nyore kuora, kukwegura.Iyo fluidity yakanaka, asi kuumba shrinkage rate ndeye 1.0 ~ 2.5%, shrinkage rate yakakura, iyo iri nyore kutungamirira kune shrinkage gomba, dent, deformation uye zvimwe zvikanganiso.Polypropylene kutonhora kumhanya inokurumidza, kudira sisitimu uye kutonhora system kunofanirwa kutonhora zvishoma nezvishoma, uye teerera kudzora tembiricha yekuumba.Ukobvu hwemadziro ezvikamu zvepurasitiki hunofanirwa kuve hwakafanana kudzivirira kushaikwa kweglue uye inopinza Angle kudzivirira kushushikana kushushikana.

1.2Kuongororwa kwekuumbwa kwemaitiro epurasitiki lunch box

1.2.1.Kuongorora kwemaitiro ezvikamu zvepurasitiki

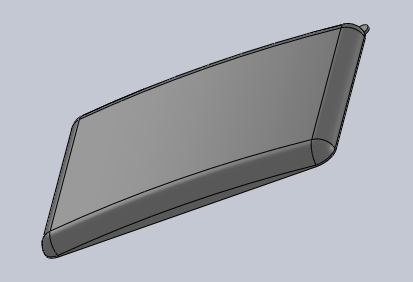

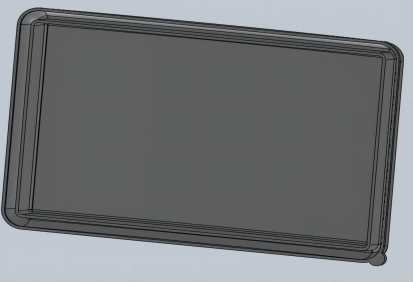

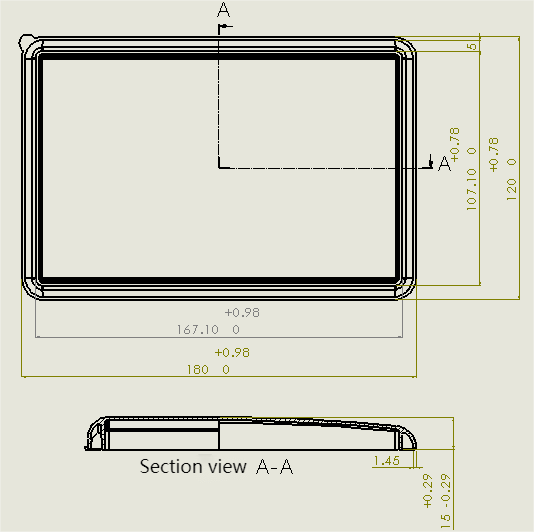

Iyo yakakurudzirwa madziro ukobvu hwe polypropylene madiki epurasitiki zvikamu 1.45mm;Saizi yekutanga yebhokisi rekudya kwemasikati ndeye 180mm×120mm×15mm;Tora hukuru hwemukati hwemadziro evhavha yebhokisi remasikati: 107mm;Musiyano pakati pemadziro emukati nekunze ndewe: 5mm;Kona yakatenderedzwa yemadziro ekunze ndeye 10mm, uye kona yakatenderedzwa yemadziro emukati ndeye 10/3mm.Imwe kona yebhokisi kavha ine annular boss ane radius ye4mm.Nokuti zvikamu zvepurasitiki zvidhinha-zvakakomberedzwa midziyo, kuitira kudzivirira kushayikwa kwekuoma uye simba kunokonzerwa nezvikamu zveplastiki deformation, saka pamusoro pezvikamu zvepurasitiki zvakagadzirirwa se 5mm yakakwirira arc denderedzwa.

1.2.2.Dimensional precision kuongororwa kwezvikamu zvepurasitiki

Iwo mativi maviri echifukidzo chebhokisi remasikati ane zvinodiwa, zvinoti 107mm uye 120mm, uye chinodikanwa chechokwadi iMT3.Sezvo chikamu chekunze chezvikamu zvepurasitiki chinokonzerwa nekushivirira kwezviyero zvechikamu chinofambisa chemuumbi (zvakadai semucheto unobhururuka), rudzi rwekushivirira runosarudzwa segiredhi B. Kana kushivirira kwepamusoro kusingadiwi, MT5 inosarudzwa. .

1.2.3.Kuongororwa kwemhando yepamusoro yezvikamu zvepurasitiki

Kurongeka kwepamusoro kwechifukidziro chelunchbox hakuna kukwirira, uye kushata kwepamusoro Ra ndeye 0.100 ~ 0.16um.Naizvozvo, iyo imwe chete yekuparadzanisa pamusoro cavity jekiseni mold yegedhi mumhanyi inogona kushandiswa kuve nechokwadi chechokwadi chepamusoro.

1.2.4.Material properties uye vhoriyamu uye kunaka kwezvikamu zvepurasitiki

Bvunza zvimiro zvePP plastiki (inosanganisira elastic modulus, chiyero chePoisson, density, simba rekusimba, kupisa kwemhepo uye kupisa kwakati) muSolidWorks, uye shandisa SolidWorks software kuverenga iyo data yezvikamu zvepurasitiki (kusanganisira huremu, vhoriyamu, nzvimbo uye nzvimbo yepakati. yesimba rinokwevera zvinhu pasi).

1.3 Sarudza maitiro ekuumba maparamita ezvikamu zvepurasitiki

Mukuita jekiseni kuumba, tembiricha ye silinda uye nozzle ichakanganisa purasitiki uye kuyerera kwepurasitiki, tembiricha ye mold inokanganisa kuyerera uye kutonhora kwekuumbwa kwepurasitiki, kudzvanywa mukuita jekiseni kuumba kuchakanganisa plasticization yepurasitiki uye zvikamu zvepurasitiki zvemhando.Kugadzirwa muchiitiko chekuona kunaka kwezvikamu zvepurasitiki kunoedza kupfupisa kutenderera kutenderera kwezvikamu zvepurasitiki, izvo nguva yejekiseni uye nguva yekutonhora zvine chekuita nemhando yezvikamu zvepurasitiki.

Mibvunzo yekufunga kana uchigadzira:

1) Kushandiswa kwakakodzera kwema stabilizers, lubricant kuve nechokwadi chekushanda kwePP plastiki uye kushandiswa kwezvikamu zvepurasitiki.

2) Shrinkage, indentation, deformation uye zvimwe zvikanganiso zvinofanira kudzivirirwa panguva yekugadzira.

3) Nekuda kwekukurumidza kutonhora kutonhora, teerera kune kupisa kuparara kweiyo yekudurura system uye yekutonhora system, uye teerera kune kutonga kwekuumba tembiricha.Kana tembiricha yekuumbwa yakadzikira kupfuura madhigirii makumi mashanu, zvikamu zvepurasitiki hazvizove zvakapfava, pachava nekusakisa welding, kusiya mavanga uye zvimwe zviitiko;Kupfuura 90 madhigirii anowanzoita warp deformation uye zvimwe zviitiko.

4) Ukobvu hwemadziro ezvikamu zvepurasitiki zvichave yunifomu kudzivirira kushushikana kwekushushikana.

1.4 Modhi uye kutsanangurwa kwejekiseni molding muchina

Zvinoenderana nemaitiro ekuumba maparamendi ezvikamu zvepurasitiki, yekutanga sarudzo yepamba G54-S200/400 modhi yekuumba jekiseni muchina,

Chikamu Chechipiri: Chimiro dhizaini yepurasitiki lunch bhokisi kavha jekiseni mold

2.1 Kutemerwa kwenzvimbo yekuparadzanisa

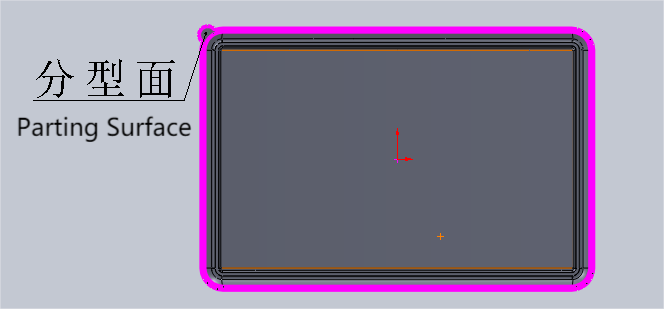

Iyo yakakosha chimiro uye yekudhiza mamiriro ezvikamu zvepurasitiki zvinofanirwa kutariswa pakusarudza nzvimbo yekuparadzanisa.Magadzirirwo emisimboti yenzvimbo yekuparadzanisa ndeaya anotevera:

1. Nzvimbo yekuparadzanisa inofanira kusarudzwa pahupamhi hwepamusoro hwechikamu chepurasitiki

2. Kusarudzwa kwekuparadzana kwepamusoro kunofanirwa kuve kwakakodzera kune yakatsetseka demoulding yezvikamu zvepurasitiki

3. Kusarudzwa kwenzvimbo yekuparadzana kunofanirwa kuve nechokwadi chekurongeka kwedimensional uye kunaka kwepamusoro kwezvikamu zvepurasitiki uye zvavanoshandisa.

4. Kusarudzwa kwekuparadzana kwepamusoro kunofanirwa kuve kwakagadzirisa kugadzirisa uye kurerutsa kwe mold

5. Deredza nzvimbo yekufungidzira yechigadzirwa munzira yekunamatira

6. Hurefu hwakareba hunofanirwa kuiswa munzira yekuvhura kufa

7. Kusarudzwa kwekuparadzana kwepamusoro kunofanirwa kuve kwakanakira kupera simba

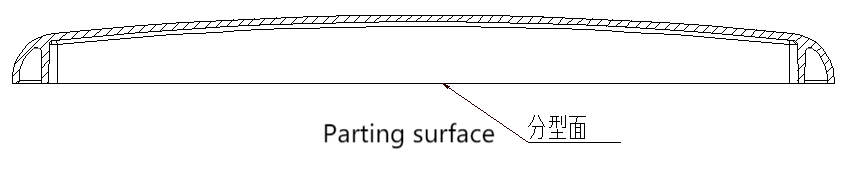

Kupfupisa, kuitira kuti ive nechokwadi chekugadzirisa kwakatsetseka kwezvikamu zvepurasitiki uye zvinodiwa zvehunyanzvi zvezvikamu zvepurasitiki uye nyore kugadzira mold, iyo yekuparadzanisa inosarudzwa seyakadzika pasi pechifukidziro chebhokisi remasikati.Sezvinoratidzwa mumufananidzo pazasi:

2.2 Cavity nhamba kutsunga uye kugadzirisa

Zvinoenderana nezvinodiwa zvekugadzira zvezvikamu zvepurasitiki dhizaini bhuku, epurasitiki zvikamu zvejometri chimiro hunhu uye dimensional kurongeka zvinodiwa uye zvehupfumi zvinodiwa zvekugadzira, sarudza kushandiswa kwegomba mhango.

2.3 Dhizaini yekudira sisitimu

Iyi dhizaini inotora yakajairwa kudurura sisitimu, uye magadzirirwo ayo misimboti ndeaya anotevera:

Chengeta nzira pfupi.

Kupisa kunofanira kunge kwakanaka,

Dzivirira core deformation uye isa displacement,

Dzivirira kutenderera kwekutenderera kwezvikamu zvepurasitiki uye kuumbwa kwemavanga anotonhora, nzvimbo dzinotonhora uye humwe hurema huri pamusoro.

2.3.1 Main chiteshi kugadzira

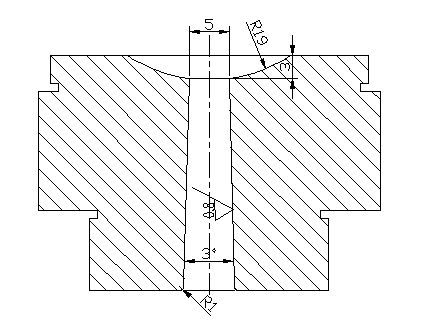

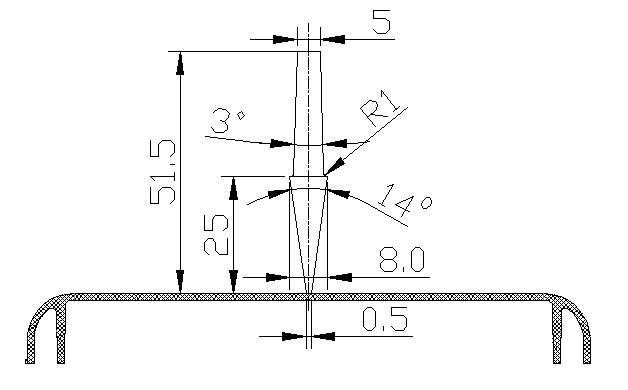

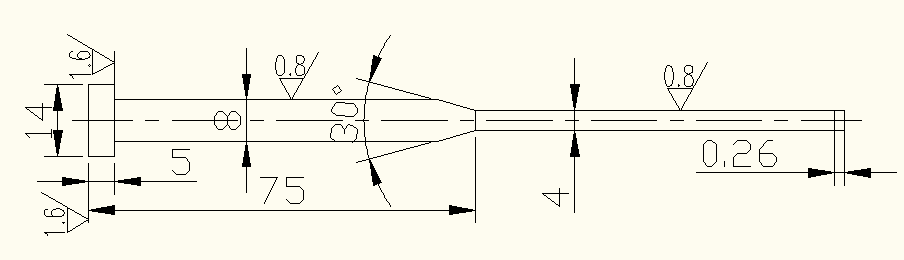

Iyo huru chiteshi yakagadzirirwa kuve conical, uye koni Angle α ndeye 2O-6O, uye α = 3o.Iko kushata kwepamusoro kweiyo inoyerera chiteshi Ra≤0.8µm, kubuda kweiyo nzira huru ndiyo fillet shanduko, kuitira kuderedza kushomeka kwekuyerera kwezvinhu kune shanduko, iyo fillet radius r = 1 ~ 3mm, inotorwa se1mm. .Iyo huru chiteshi dhizaini ndeiyi inotevera;

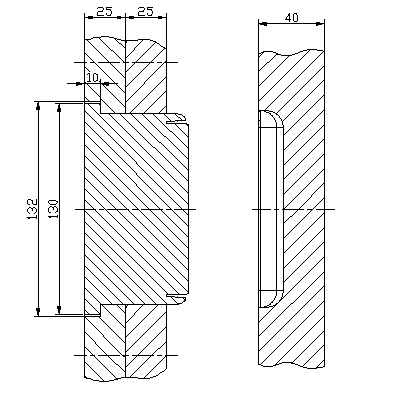

Chimiro chegedhi sleeve chakagadzirirwa kuita zvikamu zviviri uchishandisa sleeve yegedhi uye mhete yekumisikidza, iyo inogadziriswa pane yakagadzika chigaro chefa muchimiro chenhanho.

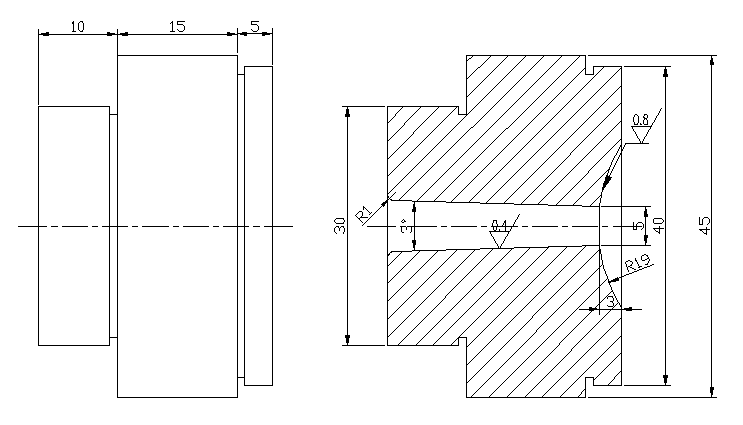

Iyo dhayamita yemucheto mudiki wegedhi sleeve ndeye 0.5 ~ 1mm yakakura kupfuura iyo yemuromo, iyo inotorwa se 1mm.Sezvo kumberi kwekupedzisira kudiki ibhora, kudzika kwayo kuri 3 ~ 5mm, inotorwa se3mm.Sezvo denderedzwa remhuno yemuchina wejekiseni inosangana uye inokodzera mold panzvimbo iyi, iyo dhayamita yechikamu chechiteshi chikuru chinodiwa kuti ive 1 ~ 2mm yakakura kupfuura iyo yemuromo, inotorwa se2mm.Fomu rekushandisa uye parameter yegedhi sleeve inoratidzwa pazasi:

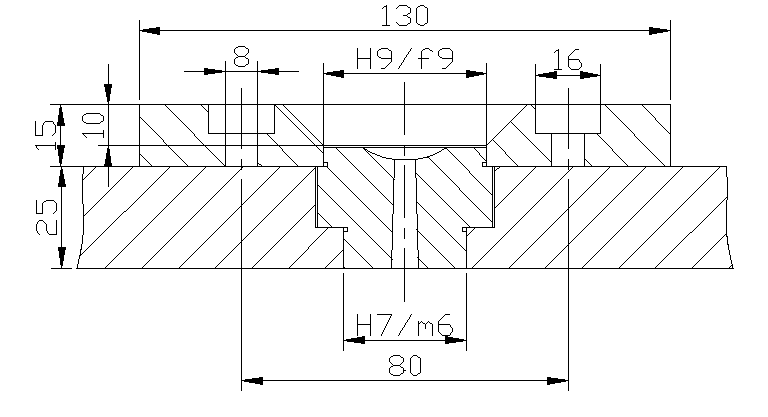

H7/m6 transition fit inotorwa pakati pechidzitiro chegedhi netemplate, uye H9/f9 fit inotorwa pakati pechidzitiro chegedhi nemhete yekumisikidza.Iyo mhete yekumisikidza inopinzwa mugomba rekumisikidza reyakagadziriswa template yemuchina wejekiseni panguva yekumisikidza uye kugadzirisa kwe mold, iyo inoshandiswa kuisirwa uye kumisa mold nemushini wejekiseni.Iyo dhayamita yekunze yemhete yekumisikidza idiki 0.2mm pane gomba rekumisikidza pane yakatarwa template yemuchina wejekiseni, saka iri 0.2mm.Iyo yakagadziriswa fomu yegedhi sleeve uye saizi yemhete yekumisikidza inoratidzwa pazasi:

2.3.2 Shunt chiteshi dhizaini

Nekuti dhizaini igomba mhango, nzvimbo yekuparadzanisa yepasi pebhokisi chivharo, uye sarudzo yegedhi reiyo point gedhi rakananga mhando, saka shunt haufanirwe kugadzira.

2.3.3 Magadzirirwo egedhi

Tichifunga nezvezvinodiwa zvekuumbwa kwezvikamu zvepurasitiki uye mold processing zviri nyore kana kwete uye kushandiswa kwechokwadi kwemamiriro acho ezvinhu, saka dhizaini yenzvimbo yegedhi inosarudzwa senzvimbo yepamusoro yevhavha yebhokisi remasikati.Iyo dhayamita yegedhi repoindi kazhinji 0.5 ~ 1.5mm, uye inotorwa se 0.5mm.Iyo Angle α inowanzo 6o ~ 15o, uye inotorwa se14o.Dhizaini yegedhi inoratidzwa pazasi:

2.4 Dhizaini yegomba rinotonhora uye tsvimbo yekudhonza

Naizvozvo, dhizaini iyi mold uye mhango, poindi gedhi rakananga kudururwa, saka gomba rinotonhora uye tsvimbo yekudhonza haifanirwe kugadzirwa.

2.5 Dhizaini yekugadzira zvikamu

2.5.1Kutsunga kwekufa uye punch chimiro

Nekuti idiki zvidimbu zvepurasitiki, mhango, uye kuitira kuti iite yakakwira kugadzirisa, zviri nyore disassembly, asi zvakare kuve nechokwadi chechimiro uye saizi yechokwadi yezvikamu zvepurasitiki, dhizaini yeiyo yakazara convex uye concave kufa kusarudzwa kwese.Iyo convex die inogadziriswa neyakasiyana nzira yekugadzirisa, uye yobva yatsindirwa mutemplate ine H7/m6 shanduko.Iyo dhizaini yedhizaini yedhizaini yedhizaini yeconvex uye iyo concave kufa ndeiyi inotevera:

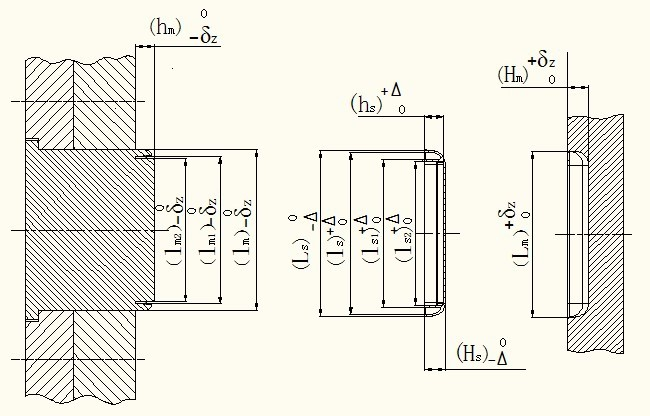

2.5.2Dhizaini uye kuverenga kwegomba uye musimboti chimiro

Hukama huri pakati pehukuru hwekushanda hwechikamu chekuumbwa uye saizi yeplastiki chikamu chinoratidzwa pazasi:

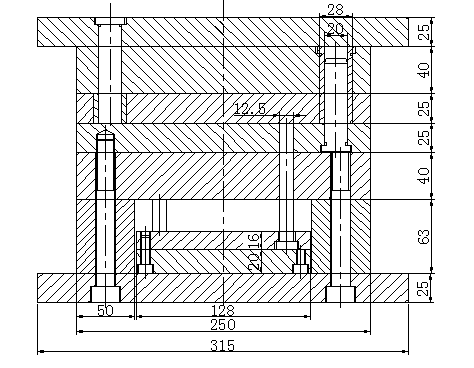

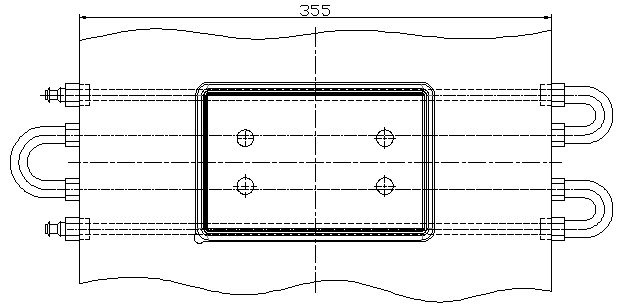

2.6 Sarudzo yeforoma frame

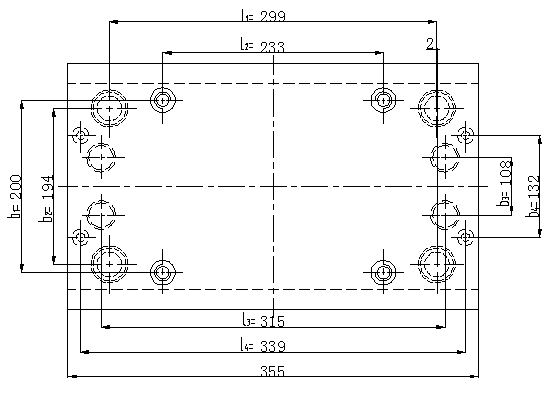

Sezvo dhizaini iyi iri yezvikamu zvepurasitiki zvidiki uye zvepakati, iyo mold furemu ndeye P4-250355-26-Z1 GB/T12556.1-90, uye iyo B0 × L ye mold frame ndeye 250mm×355mm.

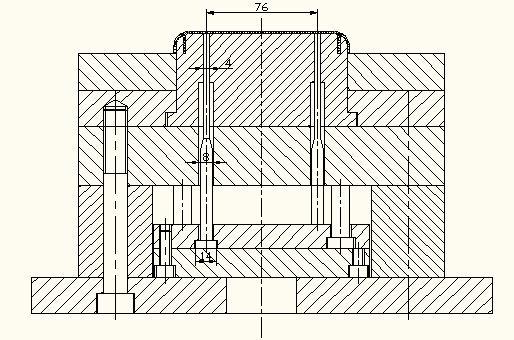

The mold assembly diagram ndeiyi inotevera:

2.7 Magadzirirwo echikamu dhizaini

2.7.1Nhungamiro mbiru yekugadzira dhizaini

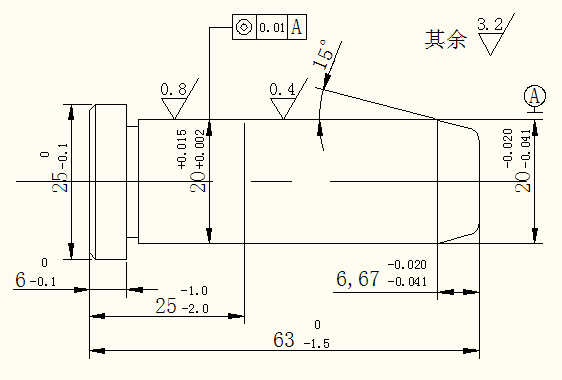

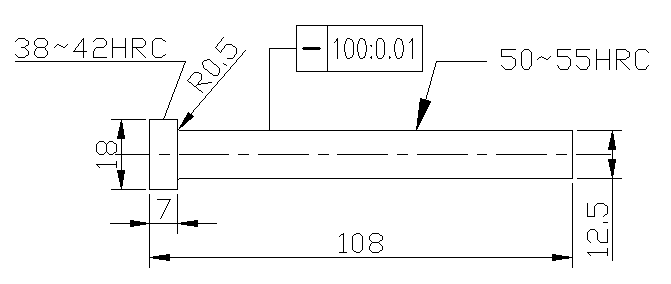

Iyo dhayamita yegidhi yepositi ndeye Φ20, uye zvinhu zvakasarudzirwa positi yegwaro isimbi makumi maviri, ine carburizing ye0.5 ~ 0.8mm uye kudzima kuomarara kwe56 ~ 60HRC.Iyo chamfered Angle inoratidzwa mumufananidzo haina kupfuura 0.5 × 450.Iyo inotungamira positi yakanyorwa se Φ20 × 63 × 25 (I) — 20 simbi GB4169.4 — 84. H7/m6 shanduko yekuchinja inogamuchirwa pakati pechikamu chakagadziriswa chegwara regwara uye template.Imwe gidhi positi yakanyorwa Φ20×112×32 — 20 simbi GB4169.4 — 84.

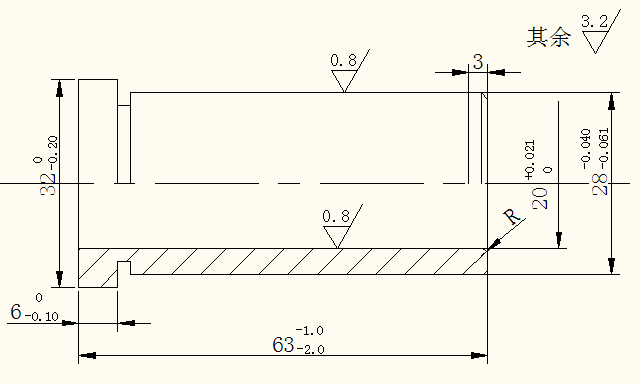

2.7.2Tungamira sleeve chimiro dhizaini

Iyo dhayamita yegwatidziro sleeve ndeye Φ28, uye zvinhu zvegidhi sleeve isimbi makumi maviri, carburized 0.5 ~ 0.8mm, uye kuoma kwekudzima kurapwa ndeye 56 ~ 60HRC.Iyo chamfering inoratidzwa mumufananidzo haina kupfuura 0.5 × 450.Sleeve yegwara yakanyorwa se Φ20×63(I) — 20 simbi GB4169.3 — 84, uye kuenzanirana kwegwara reposvo negwara remaoko ndiH7/f7.Imwe gidhi sleeve yakanyorwa Φ20×50(I) — 20 simbi GB4169.3 — 84.

2.8 Tanga dhizaini yekugadzira

Iyo yekusundira meshini inowanzo umbwa nekusundidzira, kuseta patsva uye kutungamira.

Nekuti zvikamu zvepurasitiki zvakatetepa, kana iri yekuyedza kuona kutaridzika kwemhando yezvikamu zvepurasitiki, dhizaini yekumisikidza nzira inotora ejector tsvimbo kusundira kunze zvikamu zvepurasitiki.

Iyo dhizaini dhiyagiramu yemuchina wekuvhurazviri sezvinotevera:

Chimiro uye zvimiro zvetsvimbo yekusundidzirazvinoratidzwa pazasi:

Chimiro chechimiro uye zvimiro zvetsvimbo yekugadzirisazvinoratidzwa pazasi:

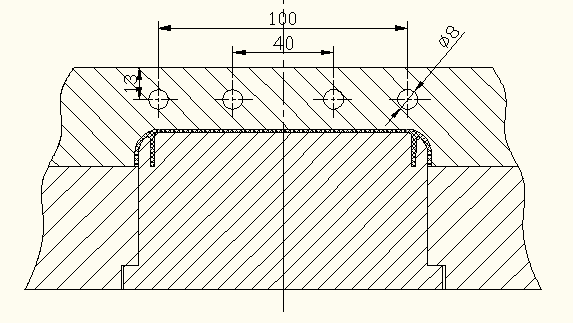

2.9 Dhizaini yekutonhora system

Sezvo kutonhora kusiri yunifomu, iyo inotonhorera inotonhorera yemugero inotonhorera inofanira kunge yakawanda sezvinobvira, iyi sarudzo yekugadzira ye 4. Iyo chiteshi chinhambwe kubva pachigadziko chepamusoro chakaenzana, uye sprue inosimbiswawo kutonhora.Iyo yekutonhodza sisitimu inotora DC kutenderera mhando, ine yakapusa chimiro uye nyore kugadzirisa.

Iyo yekutonhora system dhizaini yakaita seiyi:

Chikamu Chechitatu: Tarisa kuverenga kwejekiseni mold

3.1.Check inoenderana maitiro paramita yemushini wejekiseni

3.1.1 Tarisa huwandu hwakawanda hwejekiseni

3.1.2 Tarisa simba rekusunga

3.1.3 Tarisa rwendo rwekuvhura mold

3.2.Tarisa kukora kwemadziro emadziro uye pasi ndiro rectangular cavity

3.2.1 Ongorora ukobvu hwemadziro epadivi peakabatanidzwa rectangular mhango

3.2.2 Tarisa ukobvu hwechikamu chepasi rectangular cavity

mhedziso

Mugadziri wechikwata cheFreshness Keeper Xie Master dhizaini iyi inonyanya kugadzirwa kwechifukidziro chepurasitiki lunch box, kuburikidza nekuongororwa kwezvinhu zvepurasitiki lunch box chivharo, chimiro chezvikamu zvepurasitiki uye tekinoroji, uye zvino zvine musoro, kupedzisa kwesainzi kwejekiseni mold. design.

Freshness Keeper Izvo zvakanakira dhizaini ndeye kurerutsa iyo jekiseni mold nzira sezvinobvira kuti ive nechokwadi chemhando yezvikamu zvepurasitiki, kupfupisa kutenderera kutenderera, kudzikisa mutengo wekugadzira.Iwo akakosha mapoinzi edhizaini maitiro ekugadzira jekiseni, dhizaini dhizaini, kupatsanura kwepamusoro kusarudzwa, gating system, ejection mechanism, dhizaini yedhizaini, inotonhorera sisitimu, jekiseni rekugadzira muchina kusarudzwa uye cheki yemaparamita akakodzera uye dhizaini yezvikamu zvikuru.

Freshness Keeper's yakasarudzika dhizaini iri mudhizaini yekudurura sisitimu, kudururira sisitimu yegedhi sleeve uye yekumisikidza mhete yechikamu chimwe chete, kuve nechokwadi chehupenyu hwemuumbi, uye kusarudzwa kwezvinhu, kugadzirisa, kupisa kupisa uye kutsiva zviri nyore;Gedhi ipoint gedhi rakananga mhando, iyo inoda kaviri kupatsanurwa pamusoro, uye yakatarwa chinhambwe drawplate inoshandiswa kudzikamisa kupatsanura kwekutanga.Chimiro chacho chiri nyore uye chinonzwisisika.

Nguva yekutumira: Nov-01-2022