Plastic jekiseni molding kugadzira

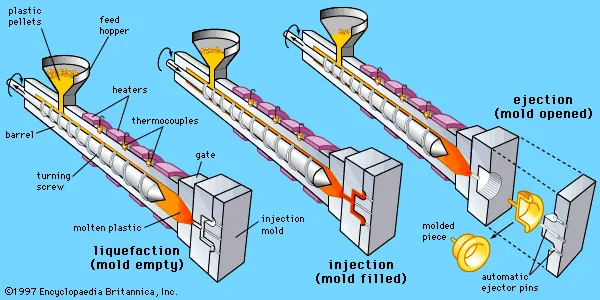

(Kuruboshwe) Mapepa epurasitiki anodyiswa kubva muhopi achiiswa muchina unodzoreredza jekiseni remajekiseni, uko anonyungudutswa nesimba remuchina rinoitwa nesiruu inotenderedza uye nemahita akarongwa pamwe chete nedhiramu.(Central) Siruuru inoenda kumberi, ichipinza purasitiki yakanyungudutswa muforoma.(Kurudyi) Mushure mekunge plastiki yasimba, mold inovhurwa uye chidimbu chakaumbwa chinodzingwa.

A Quick sumo kune jekiseni molding process

Zvinhu zvinodhura zvekuumba jekiseni

Mold tool design;Mold tool kugadzira;Polymer mutengo;Process cost

4 zvidimbu zvakakosha zveruzivo!Yako jekiseni repurasitiki mold inoda kuziva

Yakakura sei Mangani aunoda Iyo yepurasitiki zvinhu inoda kugadzirwa Kana iyo dhizaini iri kugadzira-yakagadzirira

Saizi ye molding effect:

Plastiki zvinhu mutengo;Mold tool zvinhu;Mold tool Machining nguva;Mold tool yevashandi mari;Jekiseni kuumba muchina saizi

Mangani Iwe Haukwanise kuwana zviuru zvishanu zvekuumbwa kwemutengo wakafanana wechikamu segumi zviuru zvekuumbwa.

Batch diki inoreva mutengo wakakwira zvakanyanya pachikamu;Tarisa maodha mashoma;Multi-impression mold maturusi anogona kureva mari yakakura pachikamu

Zvinhu zvipi?Chikamu chako chepurasitiki chinoda kuitei chaizvo?

UV inodzivirira?Conductive?Inoshanda pane yakakwirira kana yakaderera tembiricha?File retardant?Ruvara rwakati kana kujeka?

Zvinhu zvipi?Zvikonzero zvekuchenjerera nesarudzo yezvinhu:

Mutengo wepamusoro wezvinhu;Nguva yakareba yekutenderera;Yakakwirira mold tool mutengo;Ngozi yemazita emhando

Iyo dhizaini yekugadzira-yakagadzirira here?Iyo yakanaka dhizaini haigone kuita!

Plastic chigadzirwa dhizaini mold chishandiso dhizaini;Chinhu chipi nechipi chinogona kugadzirwa - pamutengo;Muumbi ane ruzivo achakubatsira kudzivisa zvinoshamisa

Melt processing yemapurasitiki uye epurasitiki jekiseni molding

Plastic jekiseni molding imhando yekunyunguduka kugadzirisa.'Melt' inoreva kudikanwa kwekunyungudusa marara epurasitiki (anozivikanwawo seresin) mumuchina wekuumba jekiseni kuitira kugadzira chigadzirwa chepurasitiki kana chikamu.

Plastic jekiseni molding inzira inoverengera inenge hafu yekugadzirwa kwepurasitiki.

Rudzi urwu rwezvinhu zvinoshandiswa mukugadzira jekiseni repurasitiki rinowanzo kupfupikiswa nekuda kwemamwe mazita akareba uye dzimwe nguva akaomarara emakemikari.Zvinhu izvi zvinosanganisira acrylonitrile butadiene styrene (ABS jekiseni molding), naironi (PA), poly carbonate (PC), polypropylene (PP) uye polystyrene (GPPS).Polymethyl methacrylate (PMMA jekiseni rekugadzira)

Mhando dzakawanda dzakasiyana dzezvigadzirwa zvinogadzirwa uchishandisa epurasitiki jekiseni kuumbwa kubva kune chaiyo zvikamu kusvika kune zvinhu zvevatengi.Isu tinosangana nezvakawanda zvigadzirwa zvinogadzirwa nepurasitiki jekiseni kuumba zuva nezuva.

Majekiseni akaumbwa anovaka mahedhifoni, mabhampa, madhibhodhi uye mamwe mapurasitiki akasimba emotokari dzedu, mareza emakadhibhodhi atinogera nawo, uye kunangisa mabheseni edzimba dzedu nemabhini emavhiri.

Kuumbwa kwejekiseni repurasitiki kunobvumira huwandu hukuru hwezvinhu zvakafanana kugadzirwa nekukurumidza uye ishoma lab yedu yakasimba pane semuenzaniso kugadzira vacuum.Izvi zvinodaro nekuti kuumbwa kwejekiseni repurasitiki kunoita hurongwa hwese hwekugadzira chikamu chimwe nechimwe chepurasitiki chechigadzirwa.

Kuumba jekiseni repurasitiki kunoshanda sei?

Iyo yakakosha epurasitiki jekiseni molding process inoshanda seinotevera

Muchina wekugadzira jekiseni repurasitiki une dhiramu rinopisa rine screw inodzosera mukati.

Jecha repurasitiki rinorovera mupombi inovava kuburikidza nehopi pakepisi yemuchina.

Kupisa kwebhodhoro nekumanikidza uye kukweshana kwesiruu iyo inofambiswa ne hydraulic motor inonyungudutsa purasitiki kuita fomu yemvura yakanyungudutswa.

Plastiki inomanikidzwa kumberi nescrew mupurasitiki jekiseni molding tool.